Whether in Operations, on brownfields upgrades or major greenfields capital projects, the ability to compile, share and analyse information generated and received is critical to success.

In order to enable digital operations, a digital twin and good operations practice, it is essential that information is reliable, retrievable and relevant.

ProDat has been utilised within IQ and across a broad range of clients since our inception in 2009. We are proud to have converted all the lessons, optimisations and efficiencies from these multiple projects and use cases into a single easy to use web interface.

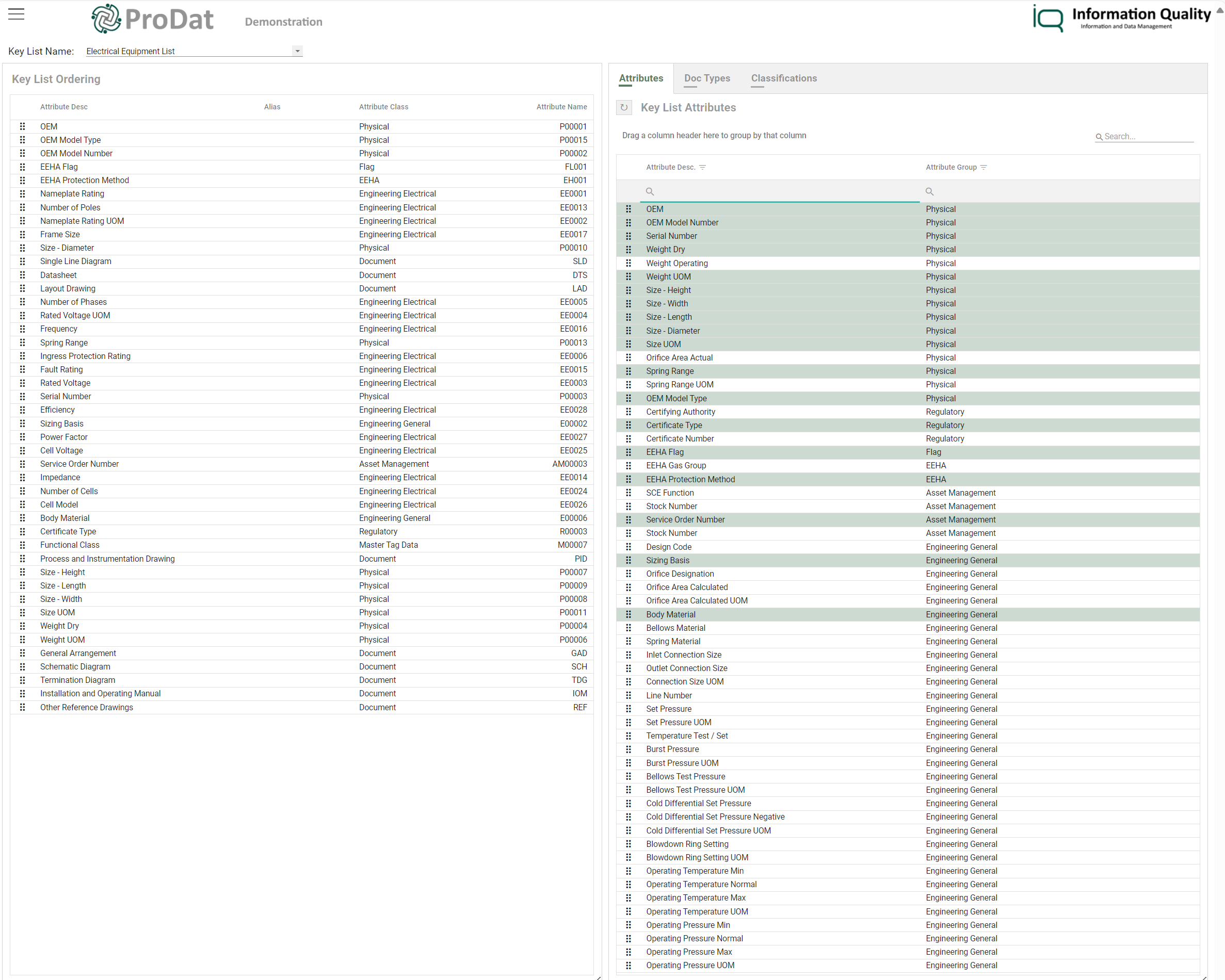

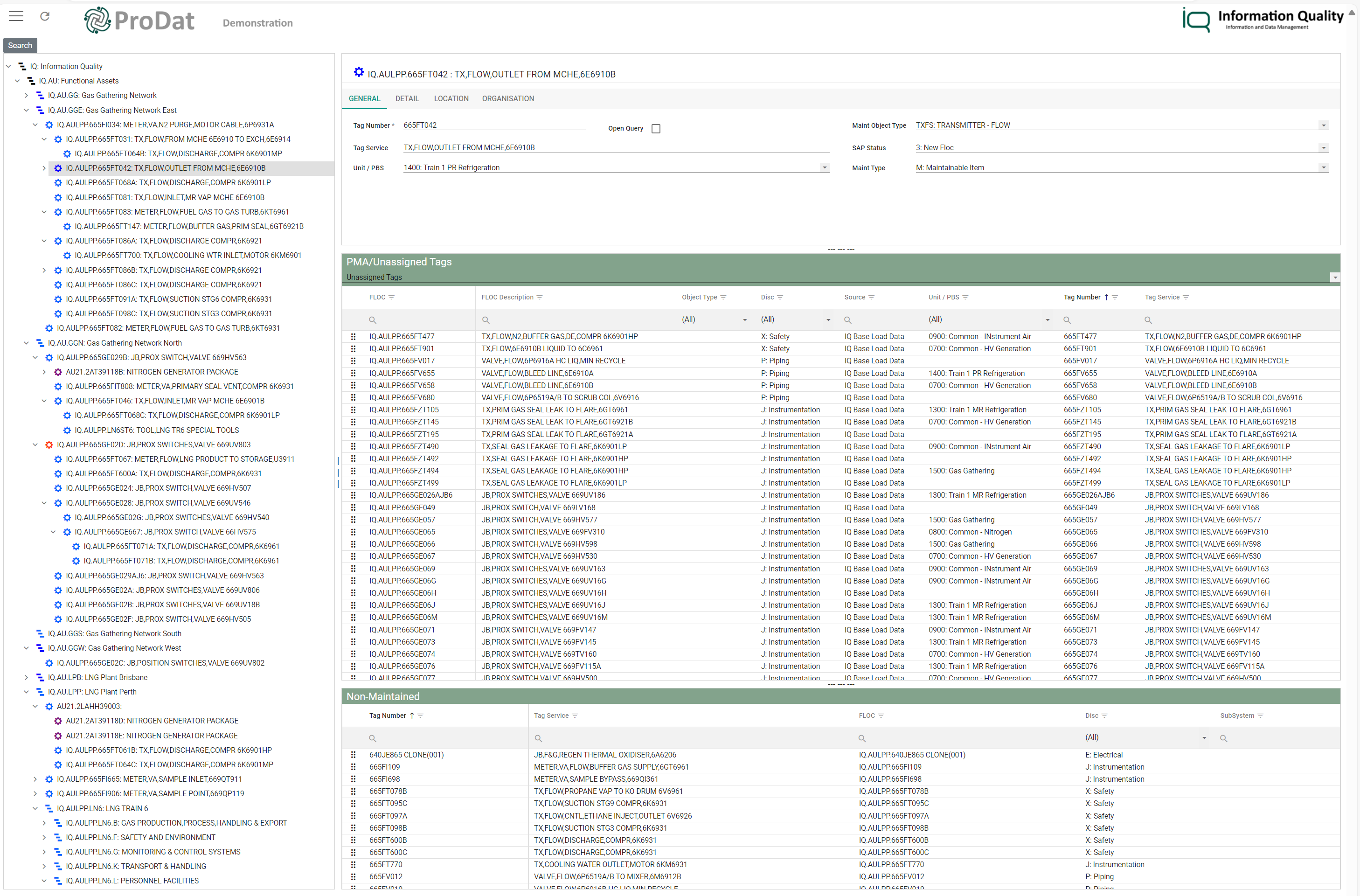

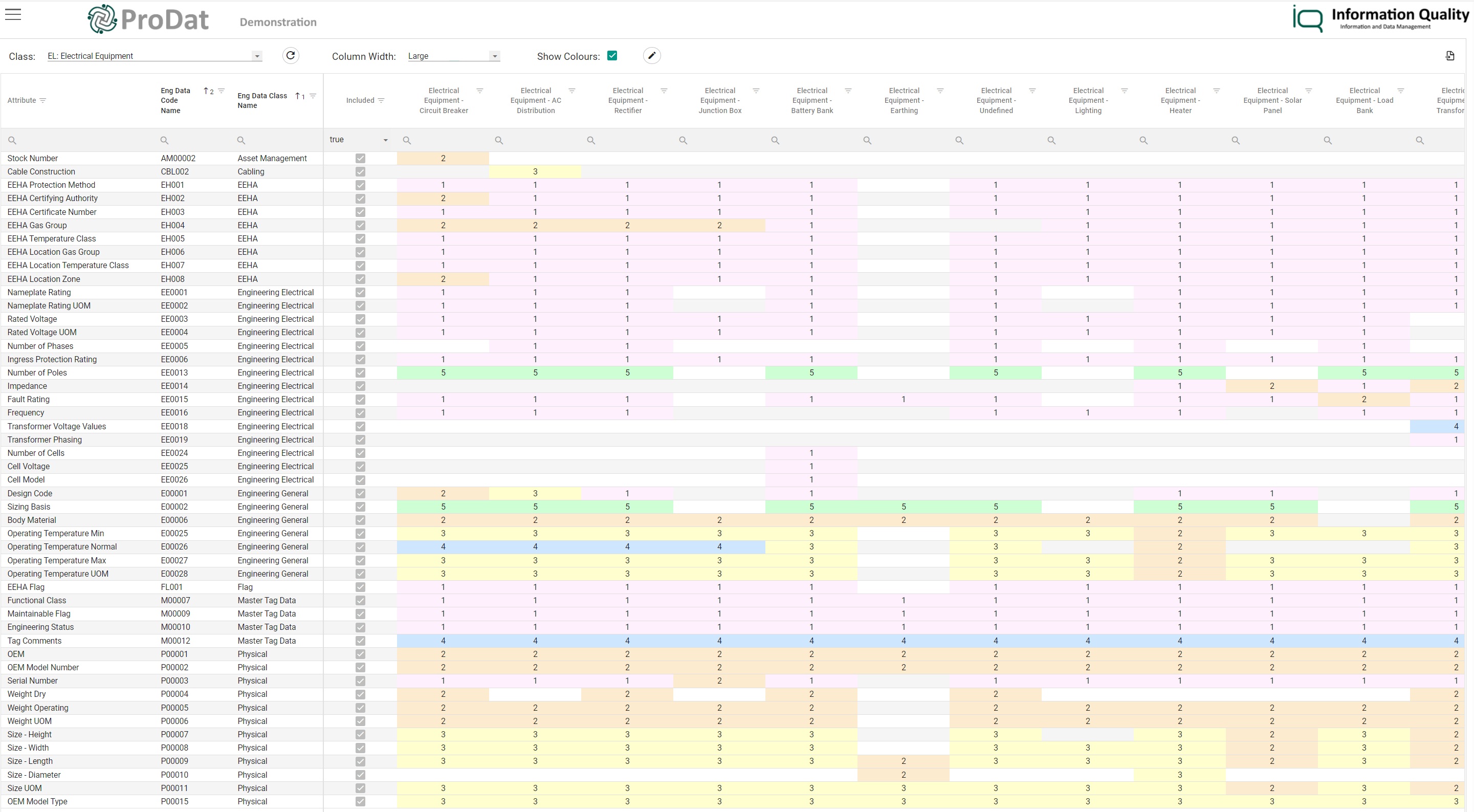

Key Lists and Class Library

Managing the Class Library and Key Lists in ProDat is simple and intuitive.

By managing information within ProDat utilising the Key list administration tools, the ability to collect, validate and manage information is enhanced and simplified.

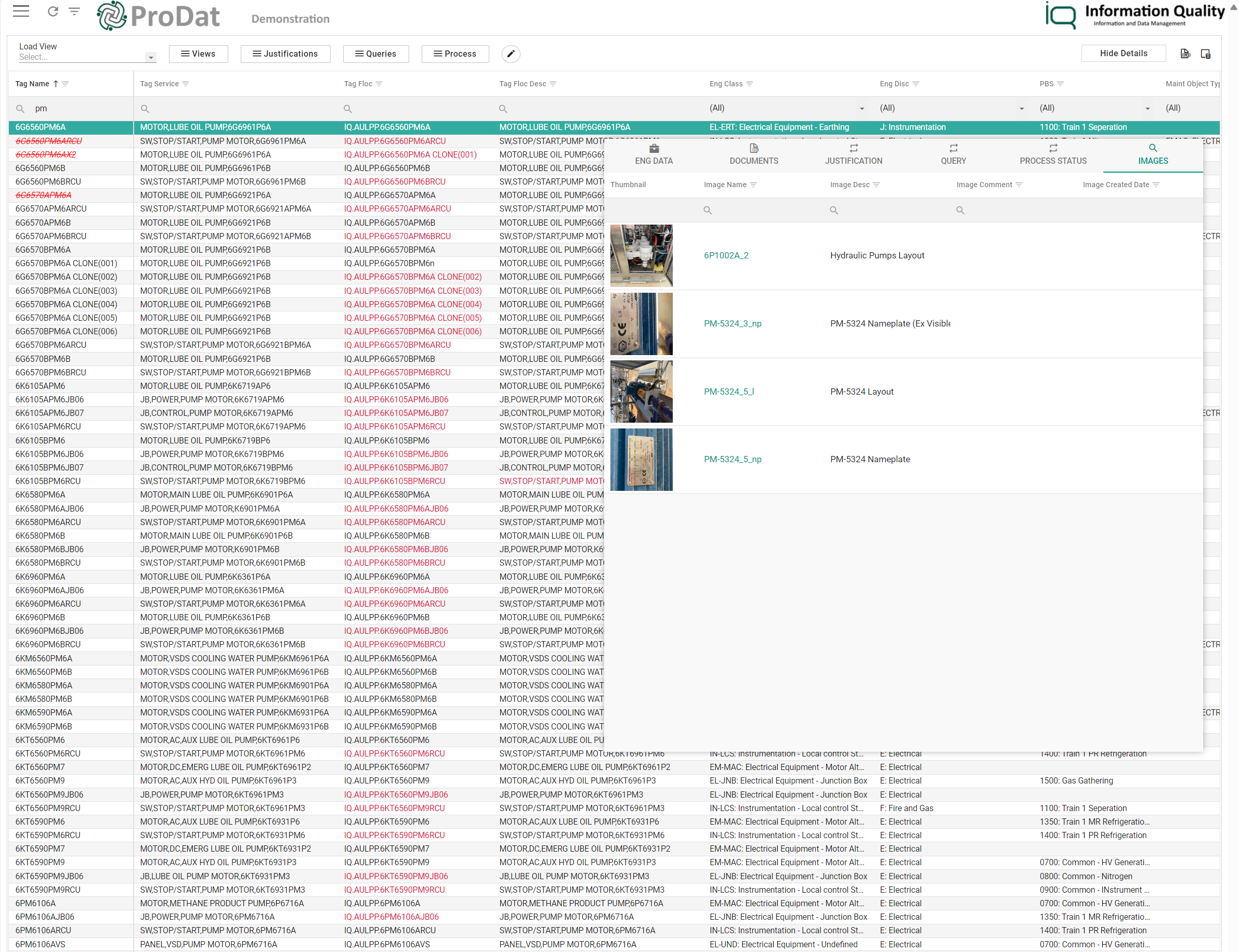

Image Management

Simple collation and retrieval of site images within ProDat creates efficiencies across the organisation.

The Tag-Image window creates simplified access to real world information globally.

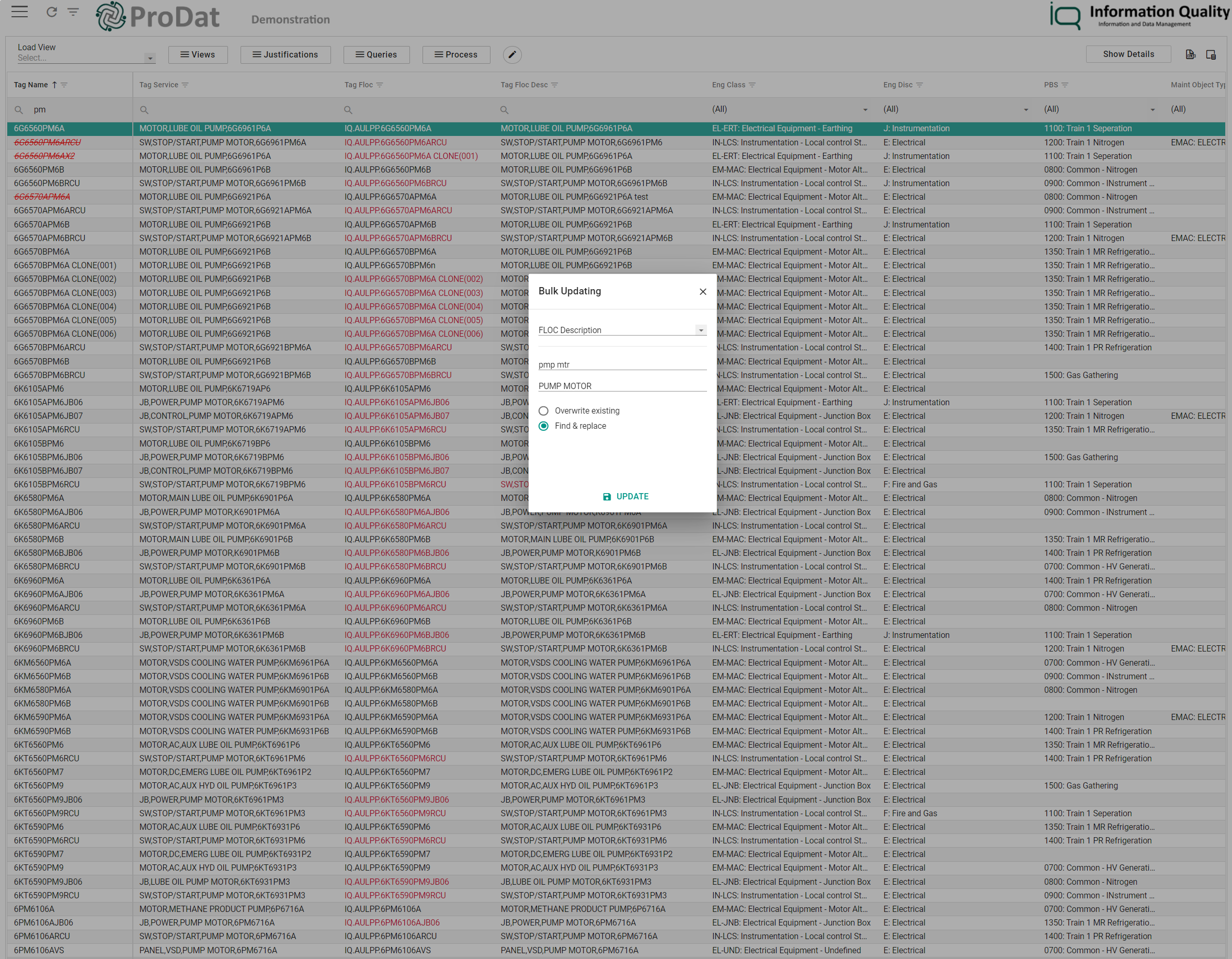

Bulk Updating

The ProDat Bulk Updating functionality increases the efficiency of information classification and editing.

Simplifying the effort by reflecting best practice workflows, ProDat increases productivity and improves reportability across the project information scope.

Site Verification

Site Information becomes available to all stakeholders and decision makers with ProDat.

With all users having access to the latest validated information, workflows are more efficient, and rework is avoided.

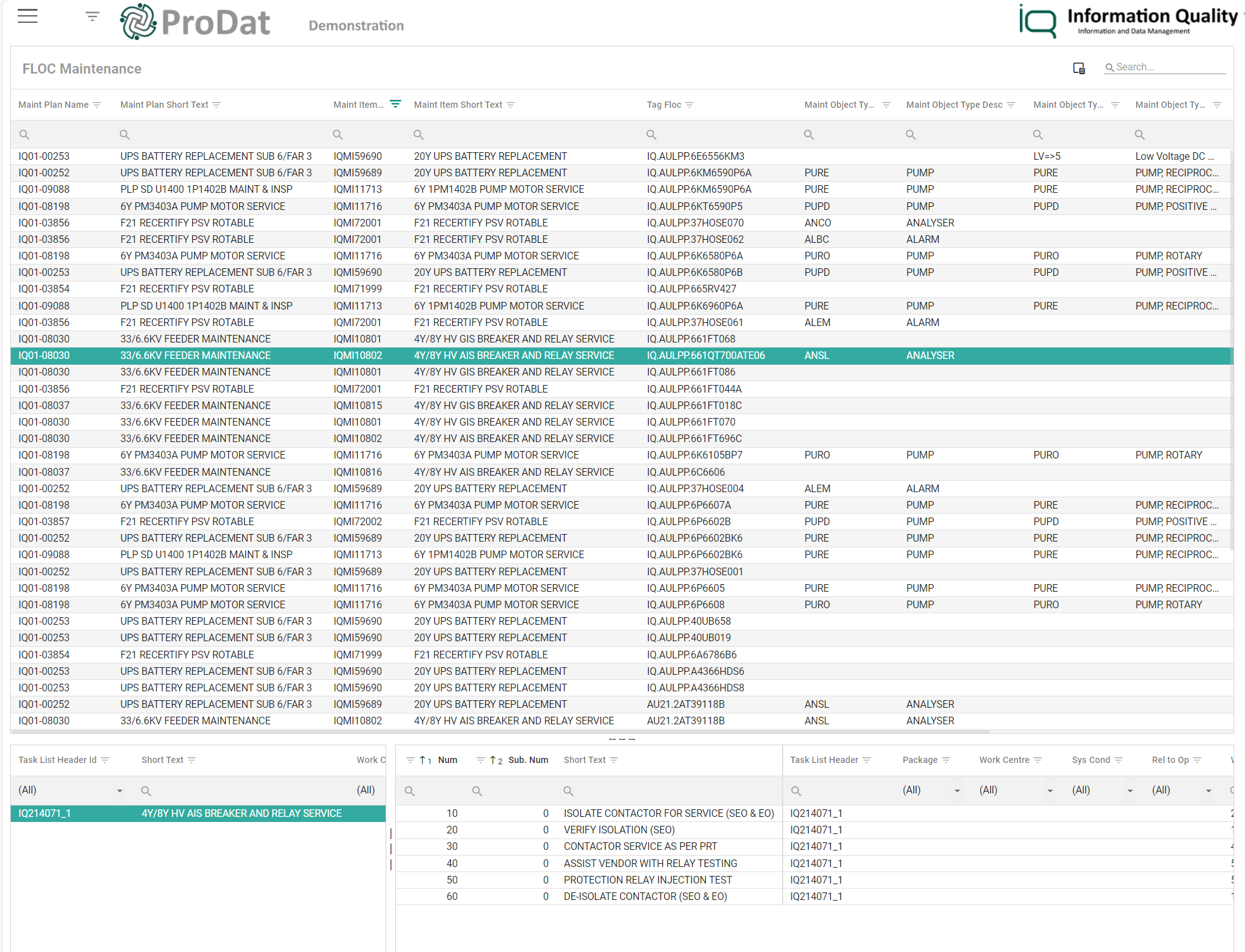

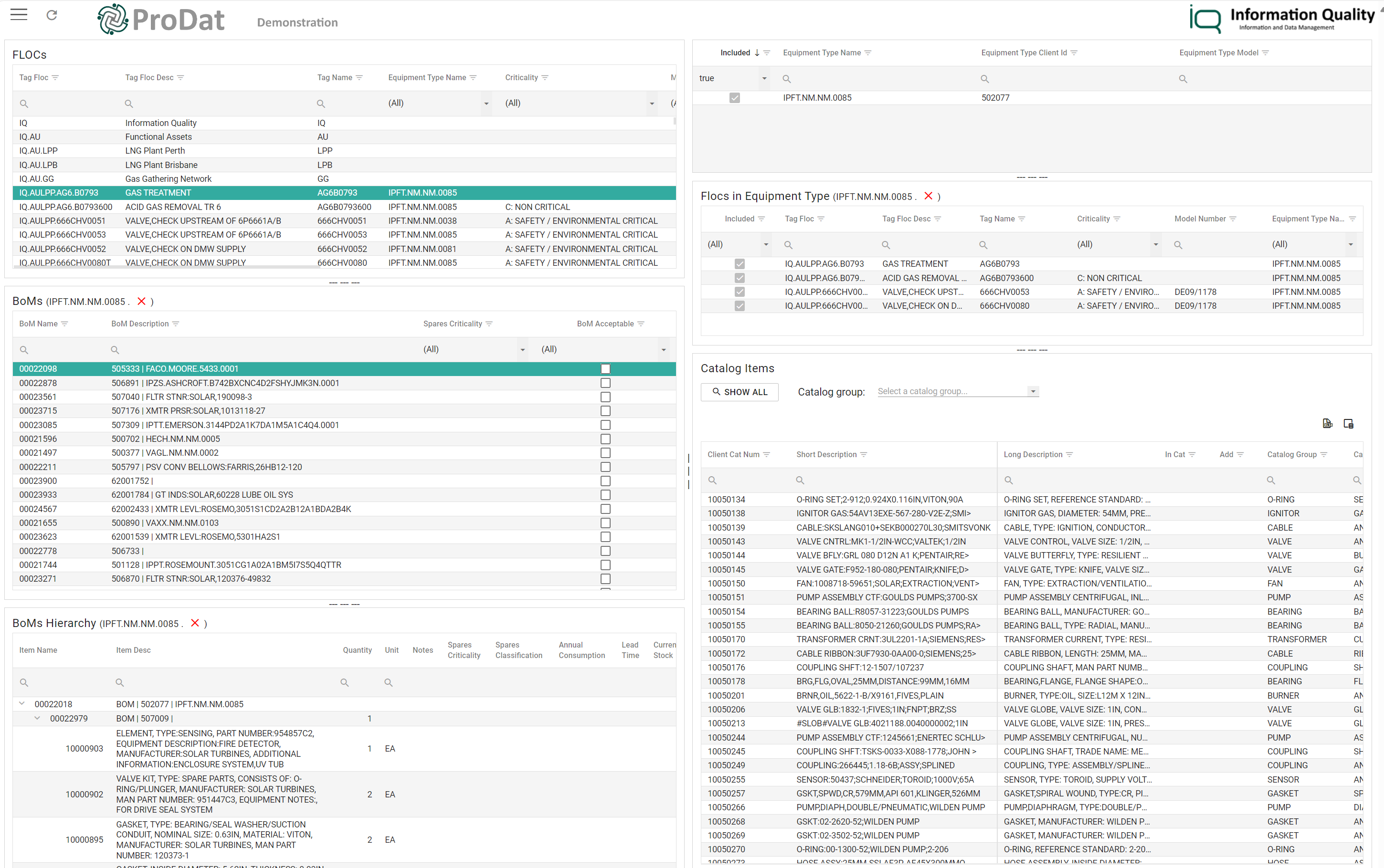

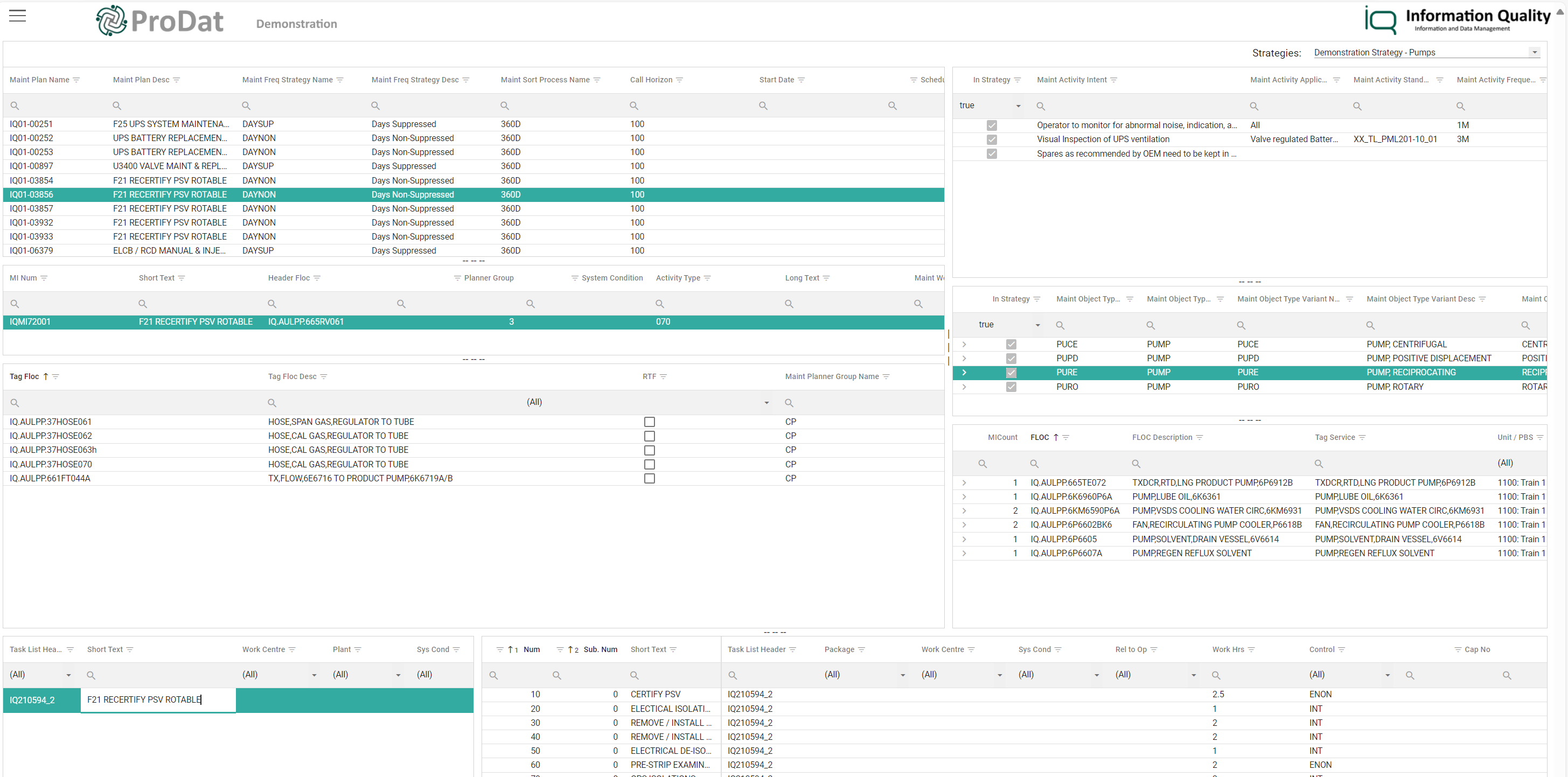

Maintenance Builds Made Easy

Whether developing a new maintenance build or manipulating an existing structure, the ability to incorporate live engineering information and visualize the final product in an intuitive and project-based platform provides maximum return on investment.

Developing, validating and sharing the maintenance and spares information in a project system enables a single consolidated load to the corporate ERP and provides the foundation for optimal performance post-handover.

Originally developed as a project tool to develop maintenance builds on megaprojects while retaining consistency with engineering information, ProDat has optimised maintenance build processes in its DNA.

From core maintenance hierarchy development and manipulation to specification of individual task actions, the complexity of an advanced maintenance build is managed within simple modules for maximum efficiency and consistency.

Maintenance Optimisation

Maintenance annualised hours are logically and easily optimised within ProDat

Generating the Asset Management build in ProDat and optimising the maintenance based on real world conditions can significantly reduce annualised hours while providing greater facility reliability and uptime.

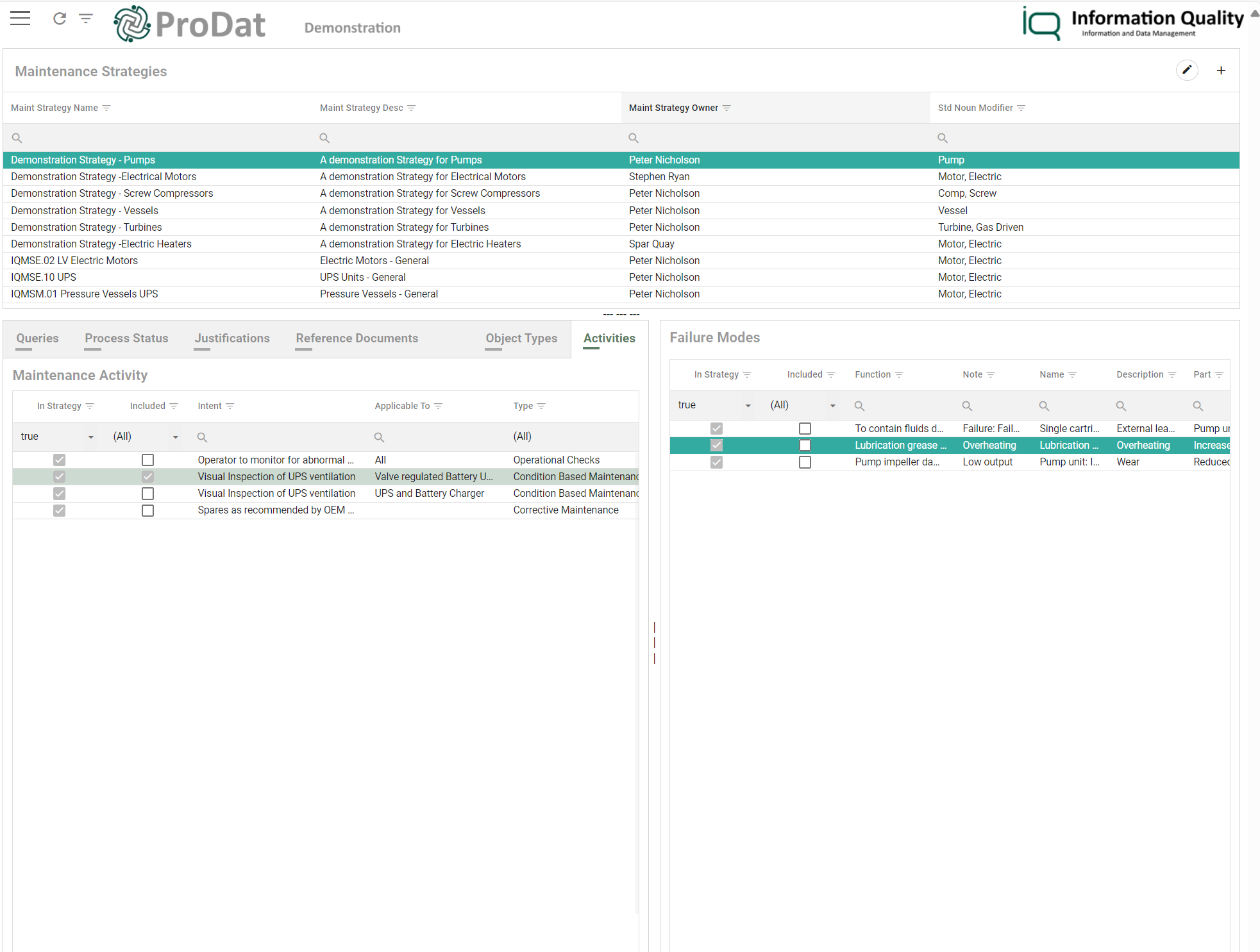

Maintenance Strategy

Development of the Maintenance Strategy is enabled within ProDat, allowing the Asset Management SMEs to associate each Object Type and variant to a specific maintenance methodology.

By linking failure modes and activities to strategies, the philosophy can be easily visualised, validated and reported upon.

Maintenance development

ProDat facilitates simplified inking of the Maintenance Strategies to the Maintenance Plans and Items.

By enabling all failure modes, maintenance activities and tasks to be visualised and connected, ProDat creates an Asset Management ecosystem which is extensive yet manageable.

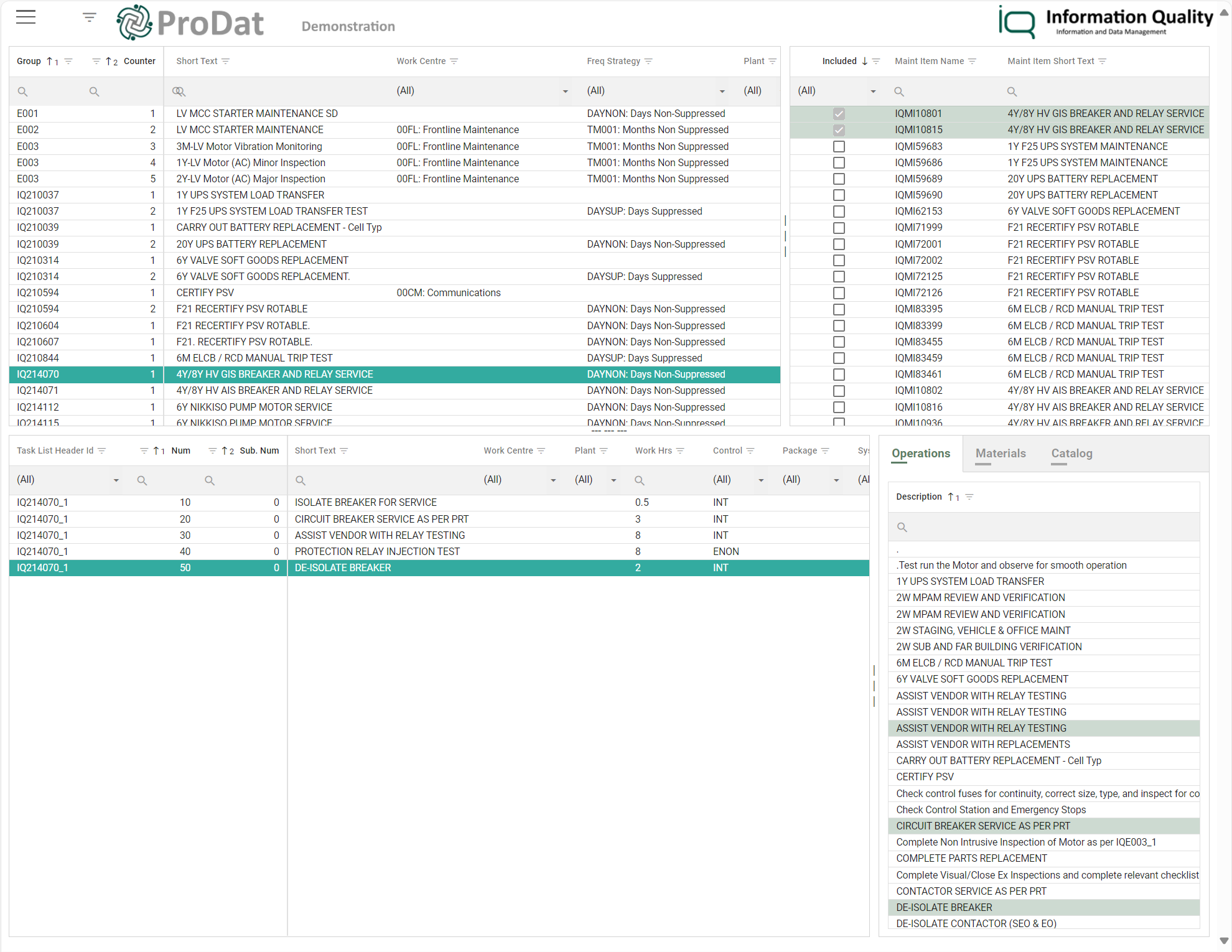

Task List Builder

The Task List Builder within ProDat provides a simple and intuitive way to develop and manipulate Maintenance works.

With a library of existing tasks, the ability to build standardised working plans is greatly enhanced.

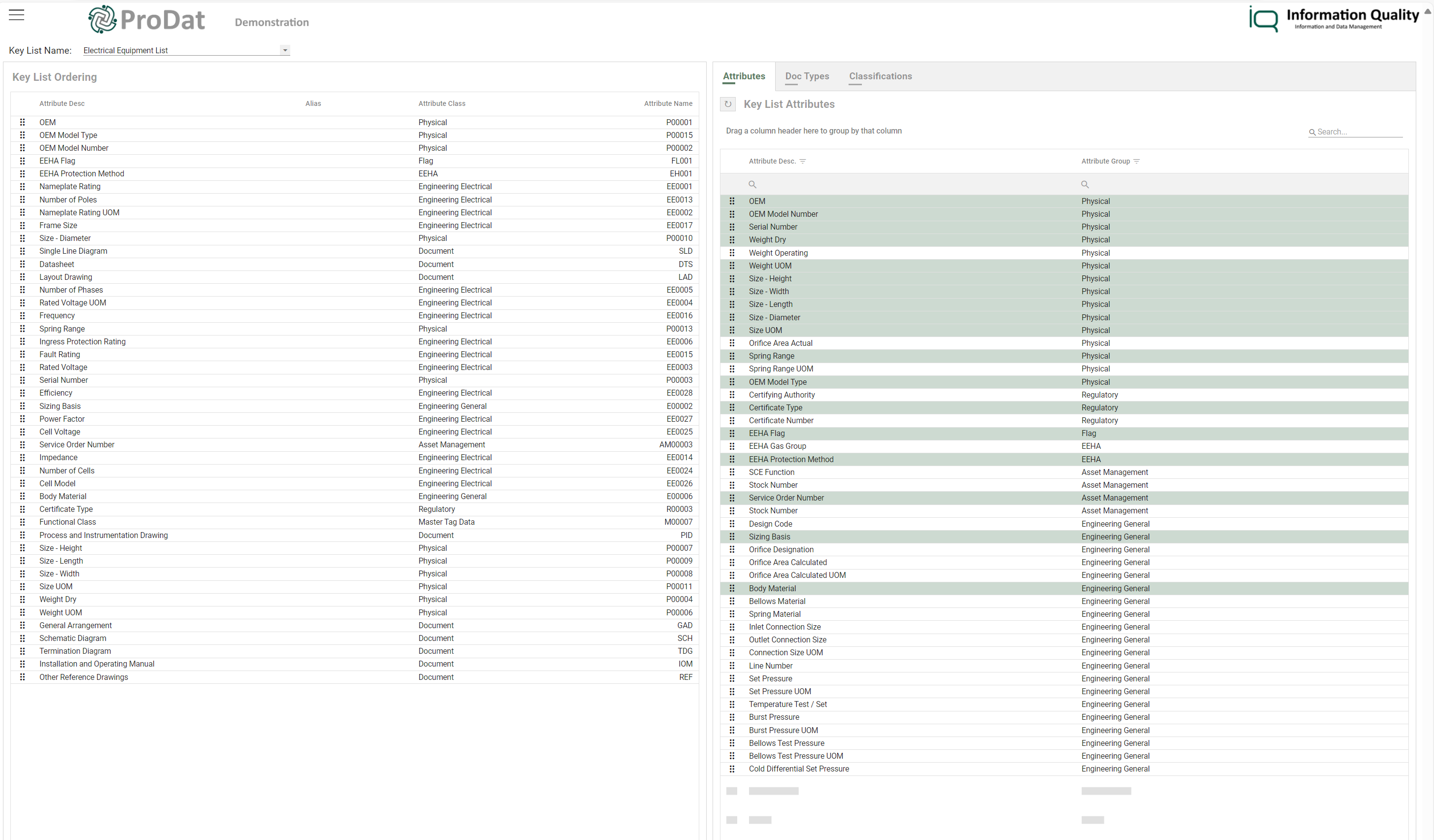

Stakeholders Informed

With ProDat, all stakeholders including engineers, operators, technicians and maintainers can access the latest trusted information in one place.

With the ability to ingest and compare unstructured, standard and bespoke data sets, and to evaluate the data between sources and across timelines ProDat provides the ideal information ecosystem for projects or operations.

Linking to project and operations documentation systems, intelligent design systems, ERPs and engineering data warehouses, ProDat supports existing enterprise systems by ensuring that a single source of truth is available for vital plant information.

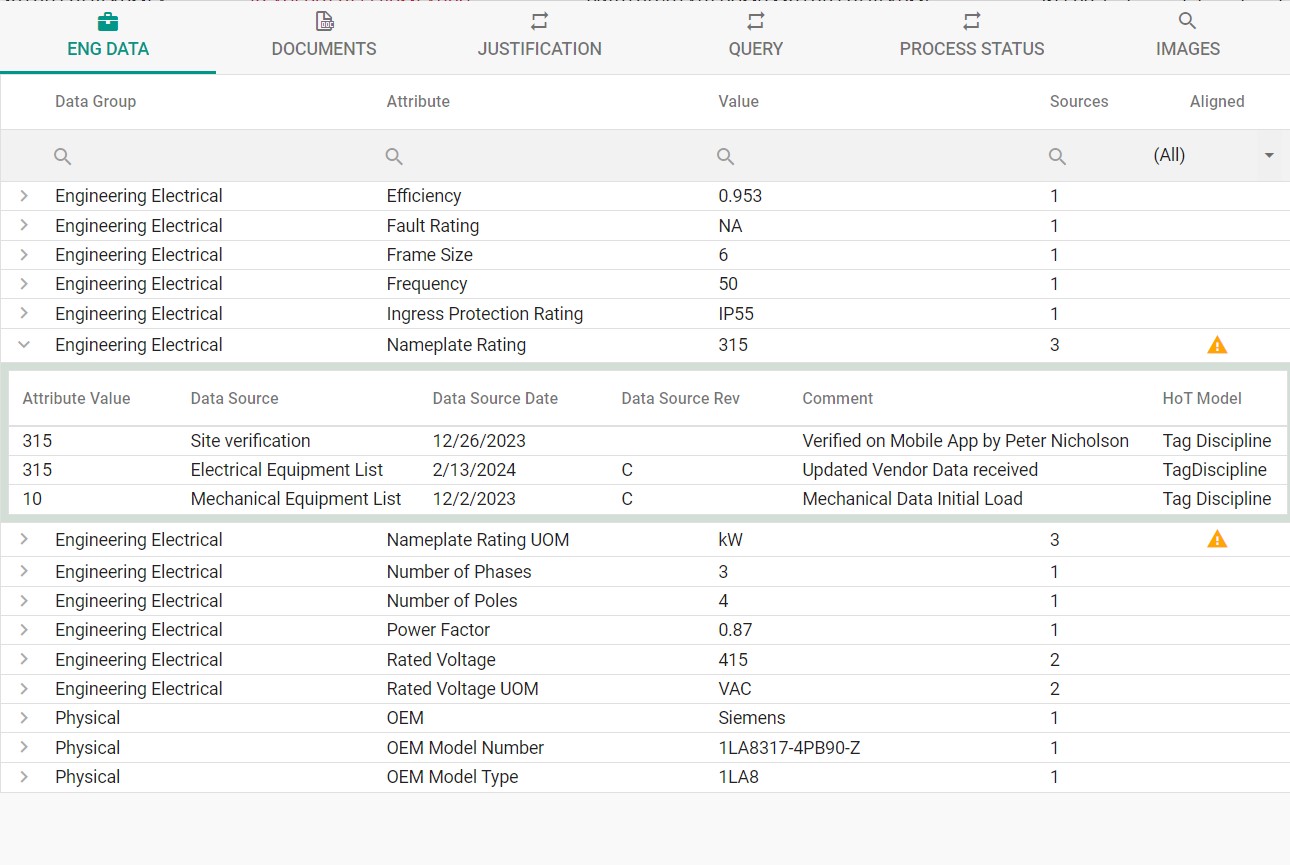

Multiple Data Sources

When multiple data sources conflict, many systems fail.

With ProDat, an out-of-the-box yet fully configurable Hierarchy of Trust enables the most trusted source of information to be surfaced. Most trusted source is dependant on the attributes of the related tag and attribute, with visual indactors flagging misaligned data and a simple methodology for viewing all data sources built in.

Image Management

Simple collation and retrieval of site images within ProDat creates efficiencies across the organisation.

The Tag-Image window creates simplified access to real world information globally.

Site Information Shared

Utilising site data and the ProDat multiple source visualisations, engineering information can be validated, managed and surfaced.

Presenting the latest site verified information and validating automatically against engineering information, updates and supply/installation abnormalities are easily identified, reported and remedied.

Query Management

The ProDat Query Management module allows users to track queries, questions and directions.

The flexibility of the query module and the ability to link to multiple tags documents and images creates the ideal solution for technical queries, internal decisions and external support requests.

Best Practice Enabled

With the ability to manage your class library and key list information directly within ProDat, information categorisation and prioritisation is simplified.

The ability to view that information which is most important to each user supports stakeholder buy-in, providing a superior handover and streamlined project acceptance.

Attribute classification, criticality and maturity is managed within ProDat for clear and concise report throughout the project lifecycle.

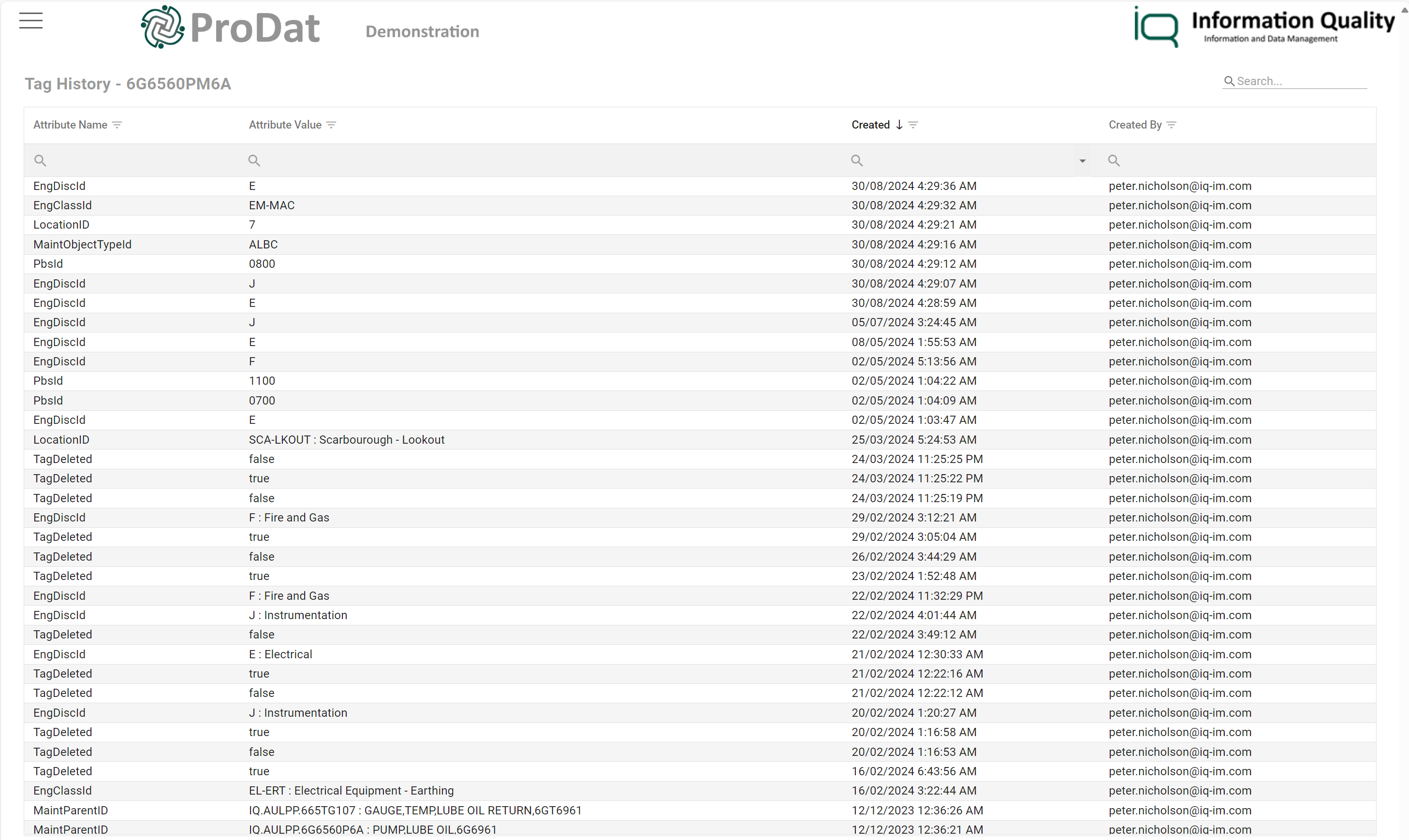

Data Historian

All additions or modifications are tracked in the ProDat data historian.

This not only provides an auditable trail of changes, but allows the 'point in time' modification view. Point in time modification views shows all changes to any given data set between any two given points in time.

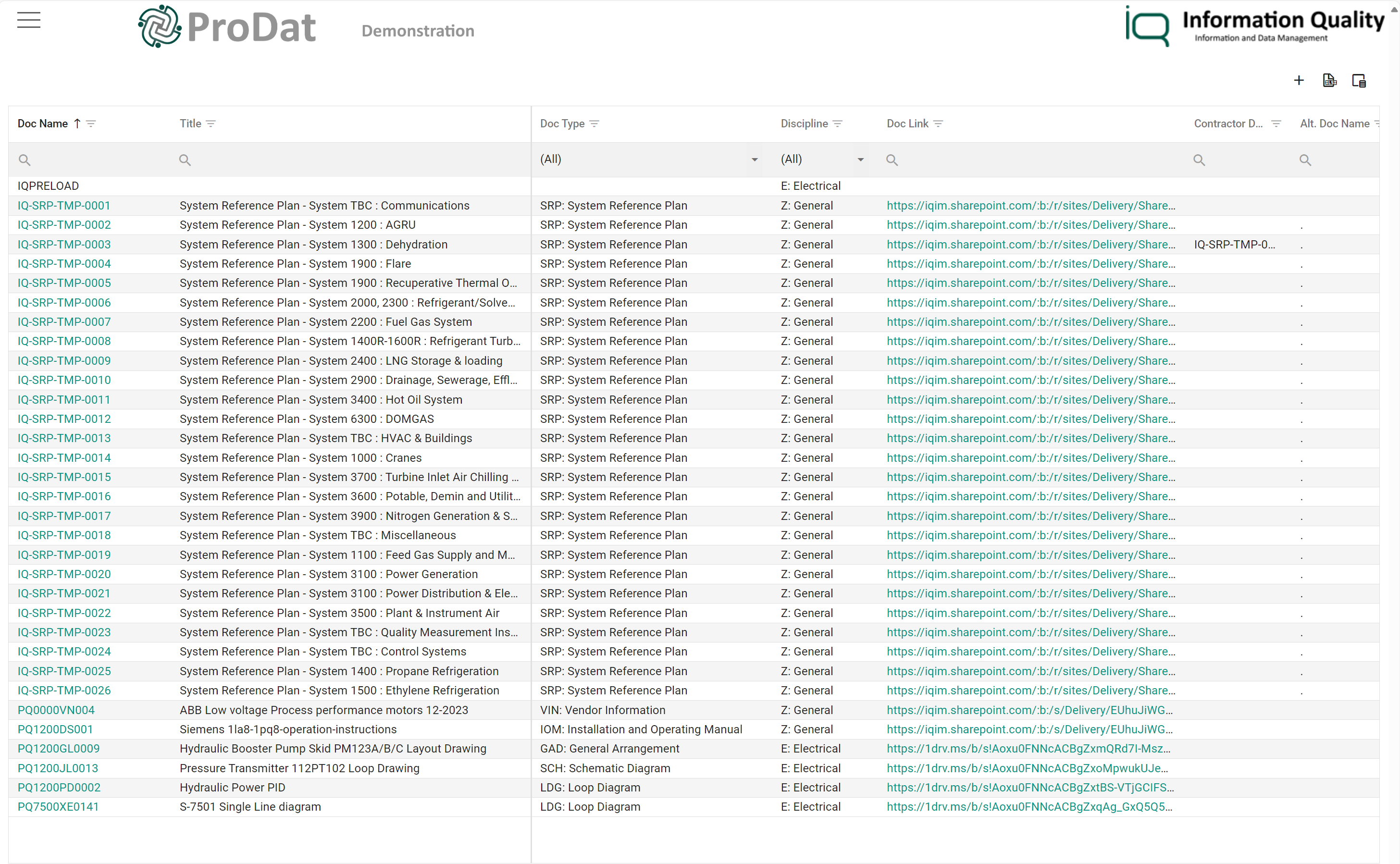

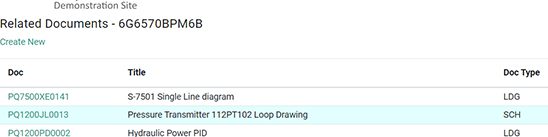

Documents and Drawings

ProDat contains a listing of all relevant Documents, Drawings and files, enabling the linking to source repositories for all information.

Linking to Contractor and Client DMS systems allows full gatekeeper functionality to remain with the DMS while directing users to the correct path for the latest revisions.

Catalog Optimisation

Warehousing efficiency and stock management is simplified and greatly enhanced with a well-managed catalog.

ProDat's advanced Catalog optimisation algorithms assist in the identification of duplicate catalog items, enabling the correct number of spares to be kept in the right place for improved reliability and uptime.

Spares Criticality and SPIRs

Evaluating the critical spares for critical equipment is simplified in the ProDat consolidated sparing interface.

Criticality assessments are able to performed within ProDat, enabling efficient and intuitive workflows. SPIR data is able to be extracted from a wide range of formats and imported into ProDat through the IQ data extraction tools, providing all required detail in a single screen.